If you like are interested in becoming one of our BHC Associates, be sure to check out our Join Our Team page!

December 7, 2023

Republic Services Opens First of Its Kind Polymer Center in Las Vegas

Republic Services Opens First of Its Kind Polymer Center in Las Vegas

Republic Services, Inc. recently opened a first of its kind polymer center in Las Vegas. The facility will promote greater plastics circularity and it is part of a larger plan for a nationwide network of polymer facilities. There is a growing demand for recycled plastic material due to several states mandating the use of recycled plastic and brands promoting and committing to sustainable packaging strategies. Supply is already struggling to meet demand and it is estimated that by 2030 demand for rPET will reach 5 billion pounds, with supply falling drastically short at an expected 2.5 billion pounds. Republic Services hopes to fill the gap with their state-of-the-art polymer recycling centers which are expected to produce 100 million pounds of recycled plastic material each year. The polymer center will be able to process plastic bottles, jugs, and containers gathered from homes and businesses to make color sorted HDPE, polypropylene, and rPET. The recycled material will be used for new sustainable packaging and other applications. In the past a recycled plastic bottle would have been downcycled into fiber to be utilized in carpets and clothing, a process that did not promote circularity. This is one of the challenges the Polymer Center is expected to solve, as with other processing methods they will be able to recycle bottles into new bottles six to seven times over, thereby extending the lifecycle of plastic packaging and promoting true circularity. Learn more here.

December 16, 2023

New Findings in Near Infrared Sorting Tech Could Improve Flexible Packaging Circularity

New Findings in Near Infrared Sorting Tech Could Improve Flexible Packaging Circularity

New data on Near Infrared (NIR) technology could boost circular design decisions and improve sortability and recyclability of flexible packaging. The Circular Economy for Flexible Packaging (CEFLEX) led a major international collaboration to uncover data centering around the design, sortability , and mechanical recyclability of flexible packaging – with an emphasis on near infrared technology and how it identifies various material structures and classifies them into different recycling streams. The data is based on testing carried out on an industrial scale involving a unique set of 240 samples and more than 100 structures. CEFLEX managed to put together the extensive set of packaging material samples by partnering with stakeholders from across the value chain. NIR is an established sorting technology in Europe and thus it is vital to obtain knowledge of its capabilities. CEFLEX design lead Liz Morrish noted, “In addition to establishing exactly how NIR sees packaging structures, the data shows how orientation, layer sequence, and opaque and reflective materials – such as carbon black, metallization, aluminum, paper – can affect the sorting outcomes and at what thresholds.” Learn more about this topic here.

December 31, 2023

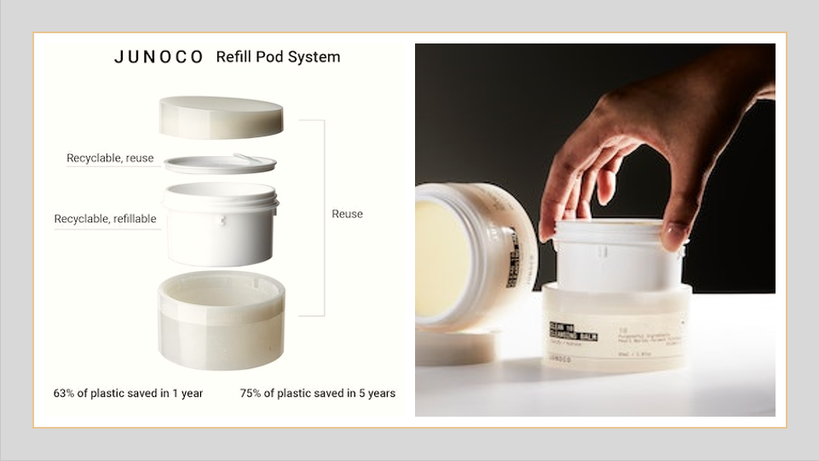

Innovative Refill/Reuse Packaging System Developed to Meet Customer Demand

Innovative Refill/Reuse Packaging System Developed to Meet Customer Demand

Skincare brand Junoco developed an innovative refillable/reusable packaging system with interchangeable pods for their products. The switch to the new packaging system came as more and more of the company’s customers requested a refill option for some of the company’s bestselling products. Once the company realized refills were in high demand, it then had to consider the customer’s experience and how to best deploy a refillable packaging system that was easy to use, durable, and hygienic. Junoco was aware that their packaging design would be an important deciding factor in driving repeat purchases, and thus they not only looked to create refillable pods but also a process in which the pods could be used with the same container repeatedly for several refills. The resulting packaging system consists of a reusable and highly durable acrylonitrile styrene jar as well as refill pods made from polypropylene. The new packaging design also featured an innovative lock/unlock mechanism which makes use of a movable ring on top of the jar and guides that are designed to match with raised guides on the refill pod to remove or secure the pod in the jar. Essentially the mechanism uses a twist and release action to either lock the pod in place or remove it for replacement. Learn more about this topic here.

© Copyright Bryan Hauger Consulting, Inc., 2018 - 2023. All rights reserved.